MAD4AM cluster

The acronym stands for “Toward a Multisectorial Accepted Development FOR Additive Manufacturing”. The Mad4AM network aims to contribute to the diffusion and acceptability of Additive Manufacturing technologies in different application sectors of the industry and health sectors.

The project is supported by the NExT (Nantes Excellence Trajectory) initiative of Nantes University.

For 3 years from 2022, the main objective will be to structure an interdisciplinary research community around Additive Manufacturing (AM) in the Nantes region. The project includes training programs and partnerships with different companies working with AM technologies.

MAD4AM is an integrated research cluster, dedicated to Additive Manufacturing (FA), managed by the CNRS and funded by NExT.

Additive manufacturing

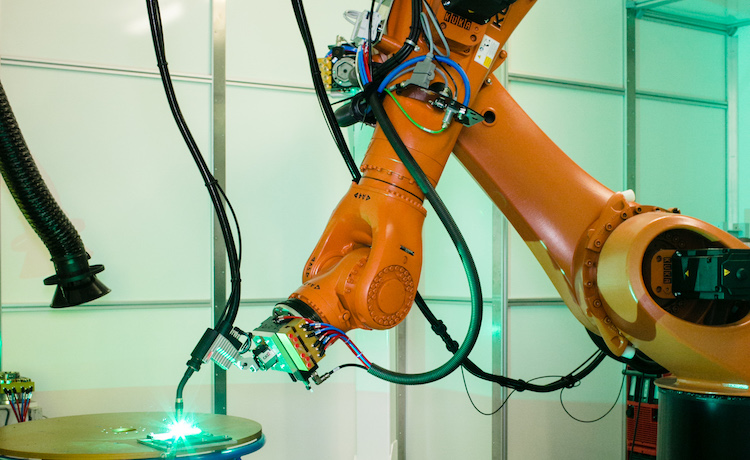

Additive Manufacturing (AM) has been forecast as the 4th industrial revolution. Indeed, its recent developments are pushing the limits of the ISO/ASTM definition: AM is a generic term for “Process(es) of joining materials to make objects from 3D model data, usually layer upon layer, as opposed to subtractive manufacturing methodologies, such as traditional machining”.

While the diversity of this family of processes is getting wider and wider, their applications extend far beyond the initial 3D printing processes designed to manufacture metallic or plastic parts without machining or moulds and with less waste products. In these first domains of industrial applications, AM now allows more complex shapes and materials combinations than traditional processes and gives more freedom to engineers for the Computer-aided design (CAD) of light weight and multifunctional structures.

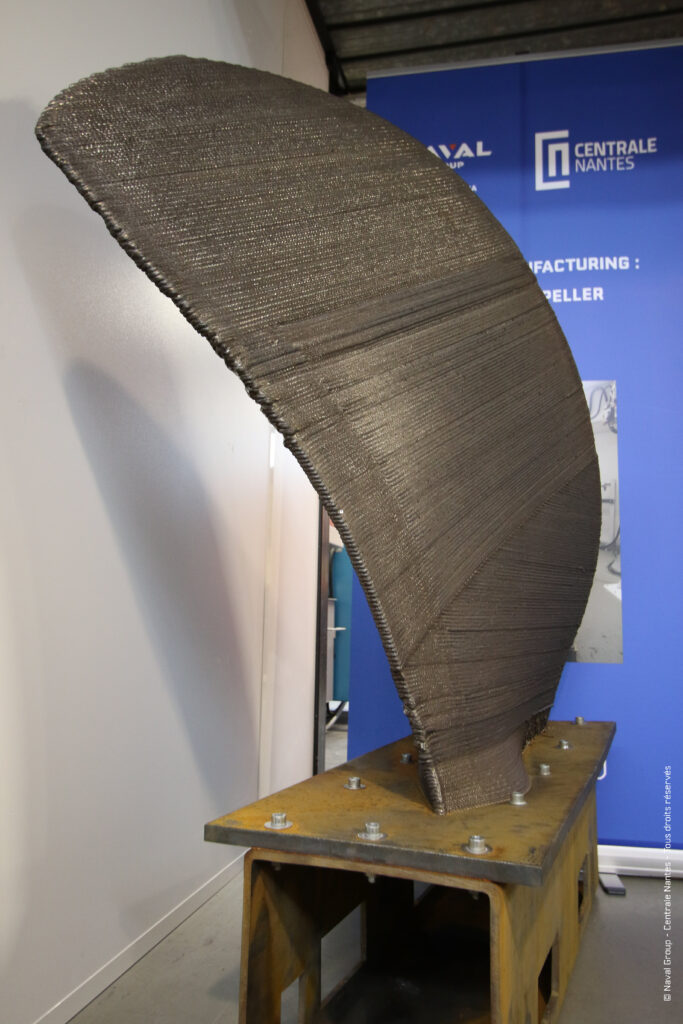

At the same time, the AM concept is diffusing faster and faster in other manufacturing sectors such as naval industry or civil engineering with the construction of free-form architectures, but also food and health concerning sectors: from medicine with the manufacture of implants adapted to the morphology of patient, to public health for example through the possibility to design and produce food products customized for a person’s nutrition.

Normal 0 21 false false false FR X-NONE X-NONE /* Style Definitions */ table.MsoNormalTable {mso-style-name:"Tableau Normal"; mso-tstyle-rowband-size:0; mso-tstyle-colband-size:0; mso-style-noshow:yes; mso-style-priority:99; mso-style-parent:""; mso-padding-alt:0cm 5.4pt 0cm 5.4pt; mso-para-margin-top:0cm; mso-para-margin-right:0cm; mso-para-margin-bottom:10.0pt; mso-para-margin-left:0cm; line-height:115%; mso-pagination:widow-orphan; font-size:11.0pt; font-family:"Calibri",sans-serif; mso-ascii-font-family:Calibri; mso-ascii-theme-font:minor-latin; mso-hansi-font-family:Calibri; mso-hansi-theme-font:minor-latin; mso-bidi-font-family:"Times New Roman"; mso-bidi-theme-font:minor-bidi; mso-fareast-language:EN-US;}

Scientific Topics and main objectives

1) Pushing the technical limits of current AM technologies:

For industrial designers and engineers, the choice of AM can be questionable: In

particular, the fact that the lack of packing pressure during the materials’

processing by AM represents a source of defects affecting parts’ quality,

performance and durability remains prohibitive for many applications.

2) Facilitating the spreading of AM in the industry of the future:

AM is already widely considered as a game changing Advanced Manufacturing Technology by many industrial sectors, in particular sectors that are strong in the regional economic ecosystem of NexT (transports, construction, food). AM is expected to bring an extraordinary flexibility in regard to the accessible geometry of industrial parts.

3) Developing the potential of AM for the health of the future:

AM opens perspectives for both Innovative Biotherapies and Precision Medicine: 3D/4D bioprinting offers unprecedented possibilities in the field of repair and regeneration. The medical researchers are enthusiast toward the possibility of linking medical imaging directly to the manufacture of prosthesis without breaking the digital chain.

The cluster's organization

The consortium brings together 12 laboratories, 2 platforms and several industrialists in sectors where Additive Manufacturing is expanding. The research teams involved have a notorious expertise in their respective fields of knowledge:

– Mechanics of materials and civil engineering (GeM)

– Functional food and biosourced materials (BIA INRA)

– Biocompatible bone materials (RMeS)

– Numerics, process control, behavior of machines and robots (LS2N)

– Heat transfer in materials processing (LTeN)

– Metallic materials and their transformations (IMN)

– (Bio)polymers, (bio)composites and multifunctional materials (IRDL)

– Fundamental and translational immunology in transplantation, autoimmunity, inflammation, infectious diseases and regenerative medicine (CR2TI)

– Neuropathies of the enteric nervous system and digestive pathologies (TENS)

– Evaluation of information systems in the field and product development (LEMNA)

– Law and technological innovations, health law, consumer law (DCS)-

Cluster's news

CableCon 2023 6th International Conf. on Cable-Driven Parallel Robots, 25th-28th of June 2023

ICEF14 – Sustainable Food Manufacturing For A Resilient Food Chain, 20-23 of Juin

MAD4AM's Cluster partners

Any corresponding result has been found for this section